How to use Fliteskin

TM

FliteskinTM can be attached to a balsa or ply frame

in 3 different ways:

1. For structural applications: Original

GorillaTM Polyurethane

glue

2. Aviation grade contact cement like

Pliobond

3.

For Non structural applications: slow curing CA (Cyano)

glue suitable for fiberglass and plastics such as Loctite 40104

Prism.

* Always sand

the areas with 80/100 grit or similar.

Application on framed wings:

-

Un-roll the

FliteskinTM

sheet in a clean table or building board.

-

Position sheets over the plans to determine

material needed.

-

Sand the entire wing top with a long T sand paper

to make sure all ribs are even.

-

Using sharp knife (box cutter) and straight edge, cut the sheet

so it overlaps 1/4"

to 1/2" (6,5mm to 12,5mm) over the leading edge and wing tips.

-

Position the skin in place over the wing (dry) and pin trough the skin in 2 or 3 places on the

Leading edge, if covering a fuselage, over a

supporting stringer. These will

be the positioning guides.

6. While positioned on the surface,

mark where the ribs, stringers and edges are located so you know

where to sand.

7. Next remove skin from frame

and sand with rough sand paper 80/100 over those areas

specially the leading edge.

8. Apply thin bids of Polyurethane Gorilla glue only

to the ribs, spars, etc. You will have about 15 minutes before

glue starts to foam.

9. After positioning the skin in place using the pin

holes previously made as a guide, place as many pins over the

leading edge as possible

making sure the entire leading edge is

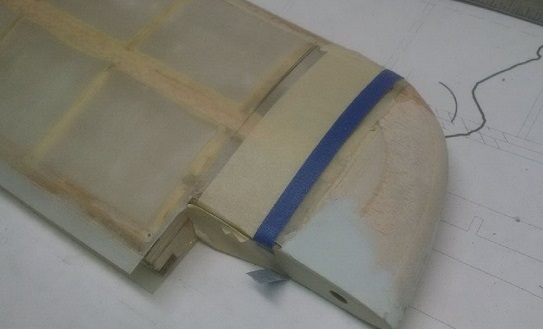

tight against the wood. See pictures below.

10.

Stack

layers of soft magazines or paper reams over the entire wing.

This work very well to ensure the skin conforms to the

frame.

DO NOT

USE WEIGHTS

10. As shown in the pictures below, a few

additional thumb tacks were placed over a few ribs. These

sometimes are needed to help with the

curvature of the wing.

11. After both Top and Bottom are sheeted you will

fiberglass the Leading edge and wing tips using strips

of glass cloth and resin.

12.

Use masking tape to define the

leading edge along the wing. Spray the L.E. with a light coat of

3M77 and position the fiberglass

cloth in place. Brush two coats

of finishing resin and let it set.

13.

Once resin has set, trim the L.E with sharp knife using the

masking tape as reference.

.

.

Application on foam wings:

Sheeting foam wings with FliteskinTM is so simple and

the results are so great that after the first use, you'll never go

back to the long and messy process of sheeting with

balsa, fiberglass and resin.

Fliteskin should be glued directly to foam cores using

Original

GorillaTM Polyurethane

glue

which is safe on foam.

1.

Prepare the foam cores as you would for balsa sheeting (cut

channels, install spars, etc).

2.

Install leading edges and wing tips. Sand even with the surface of

the foam.

3.

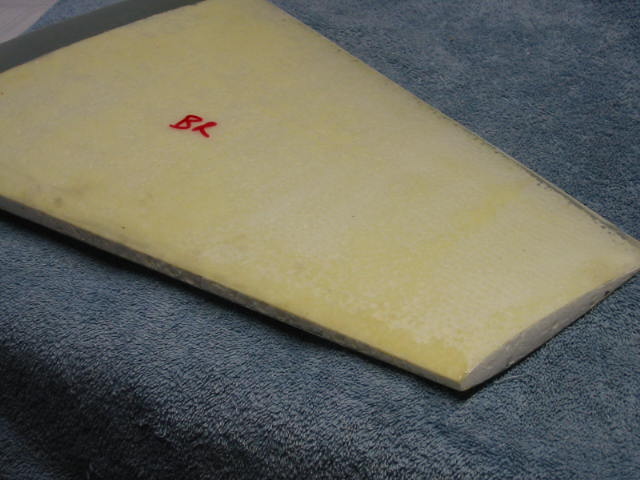

Using

a metal ruler and a hobby knife, cut the pieces of Fliteskin

TM to

fit the core (top & bottom) with an extra 1/4" or so to cover

Leading edge and/or tips. It takes about 4 or 5 scores of the

blade to cut through the sheet, alternating both sides of the

blade works best. FliteskinTM

can also be cut with

scissors but the ruler and knife method assures a straight line

cut over the plans. You can choose to add the leading edge and

wing tip after sheeting is completed but the first option

facilitates fiber glassing.

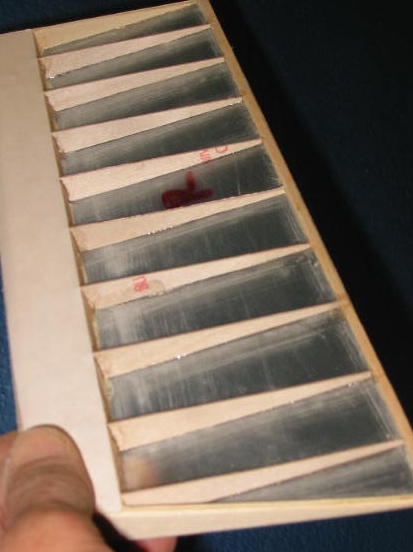

4.

With

a little experience you can glue top and bottom skins at once;

lay both pieces of sheeting flat on the table (trailing edge to

trailing edge) and join with masking tape on the outside surface.

5. The

inner side of the skins must be cleaned and sanded with 80/100

grit to increase the mechanical bonding.

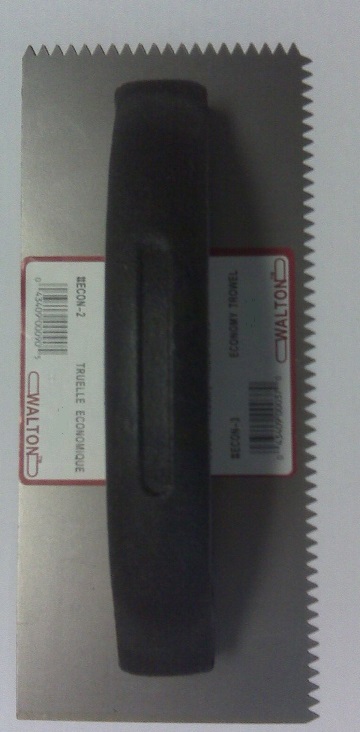

6.

Spread the glue evenly with notched side of trowel

(allows for expansion) over the COMPLETE surface of the skins. Do

not apply glue to the cores. Allow a thicker coat on the edges.

7

.

Place

assembly inside the foam cradle placing a flat board on top with

enough weight to keep from lifting.

8

.

Once

the assembly dries, it will be very rigid and strong. Now you

can cover the leading edges and wing tips with a strip of glass

cloth.

9

.

Ailerons and elevators can be cut and hinged using balsa blocks.

DO NOT apply HOT IRON directly

to Fliteskin

Frequently asked questions:

1. Is Fliteskin epoxy based? Yes, epoxy resin is the main ingredient in the sheets.

2. Is Fliteskin capable of accommodating compound curves? No. It is restricted single curves

3. Why polyurethane glue? The expansion of the polyurethane glue increases the area of contact and it works well on

wood frames.

4. What is the best technique to cover leading edges (L.E.)? Once you have the top and bottom of the wing are covered, the exposed L.E.

should be covered with a strip of fiberglass cloth and epoxy resin as described above.

5. Can it be used to cover foam wings? If you are covering foam wings, spread the glue with a trowel.

A trowel will allow only thin strips of glue and prevent too much expansion.

Copyright © 2023 Fliteskin Aeroscale